|

Novel Heterogeneous Catalysts

for Biodiesel Production

Biodiesel can be produced by

transesterification of vegetable oils or animal

fats with an alcohol, especially lower alcohols

such as methanol and ethanol in the present of

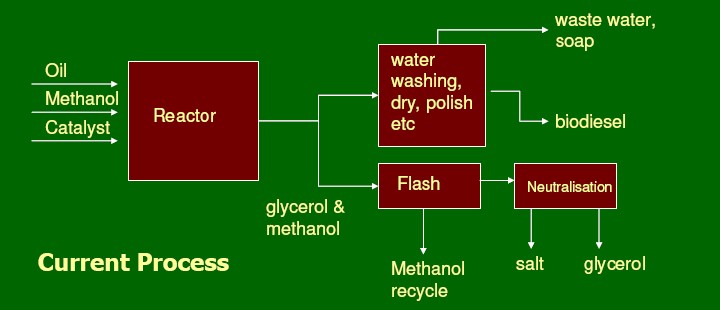

catalyst. Most commercial biodiesel industries

use homogenous base catalysts for the

transesterification process since it proceeds at

a much higher rate and produced higher

conversion of biodiesel which is over 95 %.

However, these homogenous base catalysts can not

be recovered and also necessitates a glycerol

neutralisation step.

Conventional Biodiesel

Process Using Homogeneous Catalyst

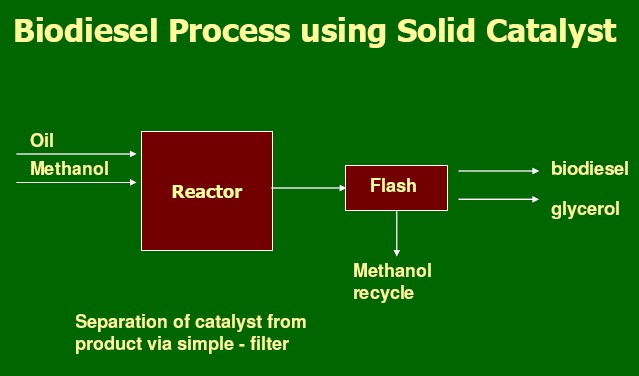

Substitution of liquid

homogeneous catalysts with solid heterogeneous

catalysts is expected to yield a cleaner product

and cheaper production costs due to reuse of the

catalyst. In this work, our effort is to develop

a new heterogeneous basic catalyst that will be

used in the transesterification of rapeseed oil

using methanol at 60oC. Our concern is on

producing an active, stable and reusable

heterogeneous basic catalyst that operates at

low temperature which has an appropriate

conversion of triglycerides into biodiesel.

Intensified Biodiesel

Process Using Heterogeneous Catalyst

Presently, we have been

looking into the polymeric adsorbent with the

quaternary ammonium functional group. It is

expected that this functional group is stable

without leaching and the conversion can be

improved to above 50 % by increasing the amount

of catalyst.

For more information please contact

Prof Adam Harvey.

|