|

Evolvable Process Design

(EPD)

The process industries in 2020

will need to produce new products more rapidly

and flexibly than ever before.

The Evolvable Process Design

(EPD) concept is to develop a chemical reactor

system that allows the evolutionary discovery of

molecules, materials and processes. The concept

consists of three parts: development of a

chemical process system, development of an

integrated genetic algorithm feedback control

system and the use of chemical building blocks

that can reversibly bind together to form a

range of molecules .

EPD is a multidisciplinary,

multicentre EPSRC-funded project, involving

chemists, chemical engineers and physicists,

from Newcastle, Glasgow, Brunel, Warwick and

London City universities.

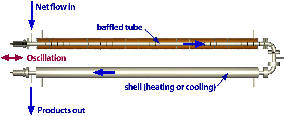

At Newcastle we will be

developing the laboratory scale process, which

will include feeds, reactor and downstream unit

operations. It will be designed and built to be

intrinsically scaleable and flexible in

operation. The unit will be continuous and

operate in plug flow (see Figure 1). The final

EPD will be designed so that the sequence of

unit operations can be reconfigured online. The

EPD system aims to utilize feedback and select

mechanisms based on spectroscopic properties of

the system/molecules/materials being evolved

(see Figure 2).

Development of the EPD will

lead to order of magnitude changes in

time-to-market of new products.

Fig. 1 - A schematic of the Oscillatory

Baffled Reactor (OBR)

Fig. 2 - A schematic of one possible EPD

platform

|