|

Intensification of Biobutanol

Production

Biobutanol is a high value

biofuel and potentially a better fuel extender

than ethanol. The market demand is expected to

increase dramatically, if biobutanol can be

produced economically via the ABE (acetone,

butation, ethanol) fermentation. ABE

fermentation performed by Clostridium species

can be divided into two distinct phases,

acidogenic and solventogenic phases. Acetic acid

and butyric acid were produced during the

acidogenic phase, and after that acetone,

butanol and ethanol were produced during

solventogenic phase. In general, the biphasic

metabolism of Clostridium species is directly

associated with cell growth status.

Exponentially growing cells mainly produce

acids, while solvent is usually produced when

cells enter the late exponential phase. If

solvent production could be initiated in early

exponential phase, the solvent productivity

might be increased as the fermentation time

would be shortened. In industry, established

fermentation technologies are using several

parallel static vessels in staggered sequence to

provide a steady flow of fermentation broth and

to overcome inhibition. This requires a huge

floor space to accommodate multiple process

equipment which leads to increase in capital

cost. In addition, several intrinsic problems

(such as low solvent yield, expensive raw

material and costly recovery process) also

contribute to the incompetence of this

fermentation compared to the chemical route.

One way to develop an

economic production route of this ABE

fermentation is through intensification of the

fermentation process to improve solvent yield

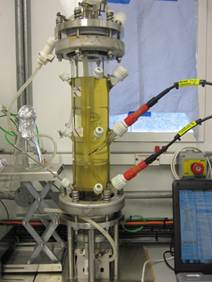

and productivity. In this work, a novel

intensified bioreactor called the oscillatory

baffled bioreactor (OBB) was evaluate for this

process (Figure 1).

Fig. 1 - A 2 L Batch oscillatory baffled bioreactor

This novel bioreactor works

by oscillating the fluid in a baffled column,

thereby producing uniform efficient mixing

throughout the bioreactor via eddy generation

due to the interaction between the orifice-type

baffles and the periodically reversing flow. The

resultant radial and axial velocities are of the

same magnitude; resulting in uniform mixing in

each inter-baffle region, along the length of

the column. One particular advantage of the OBB

is for performing ‘long’ reactions (such as

fermentations) in a more compact design than

conventional tubular plug flow reactors. A

further advantage for the ABE fermentation could

be that the OBB provides relatively low shear,

uniform mixing, thereby achieving homogenous

conditions, with less cell damage than

comparable stirred tank reactors.

For more information please

contact Prof Adam Harvey.

|