|

Scale up of oscillatory

helically baffled reactors

The Oscillatory Baffled Reactor (OBR) is an

intensified design of continuous plug flow

reactor (PFR) in which plug flow behaviour can

be achieved at very low net flow rates (laminar

flow regime). OBRs consist of tubes with

periodically spaced baffles of various designs

(orifice, helical, integral, etc). There is a

net flow through the reactor, and a superimposed

oscillatory flow. Resultantly, the OBR’s niche

application is to operate “long” reactions in

continuous mode. This is usually impractical in

conventional tubular reactors.

Scale-up of conventional reactors, e.g. stirred

tank reactors, is unpredictable due to the

non-uniform mixing at large scale, leading to

variations in the concentrations and

temperatures. This means that optimum conditions

obtained from laboratory scales cannot be

directly used at large scales without

re-optimisation. Therefore, process development

time and product-to-market times would increase.

However, scale-up of OBRs should be more

predictable, as the flow structures produced at

5 mm scales (diameter) can be reproduced at

larger scales (25–200 mm diameters).

Recent studies on oscillatory helically baffled

reactors (OHBRs) at small scales (millilitre

volumes) found that the helical baffle design

could provide high degrees of plug flow across a

broad operating window due to the combined

effect of vortex formation and swirling. In this

study, the scale-up characteristics of helically

baffled OBRs are being explored using the

residence time distribution (RTD).

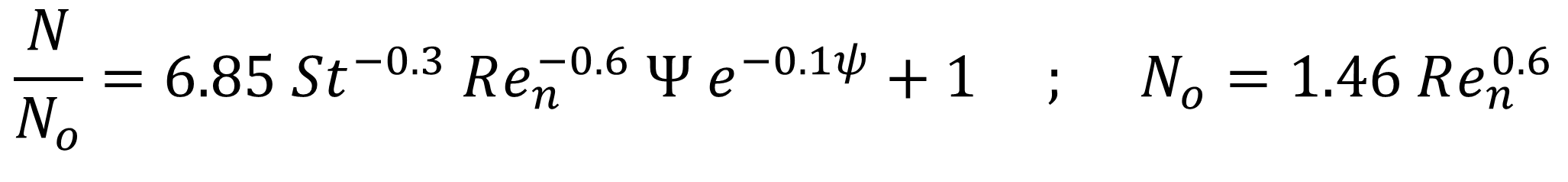

It has been found that the behaviour of RTD is

the same at all tested scales (10–25 mm

diameters, with respective reactor volumes of

0.078 L and 0.834 L) when the geometric and

dynamic parameters are maintained. The degree of

plug flow was quantified in terms of the number

of equivalent tanks-in-series (N). At a fixed

geometry, a scale-up correlation was established

and validated over a range of operating

conditions such as oscillatory conditions (Strouhal

number,

St,

and oscillatory Reynolds number,

Reo)

and the velocity ratio of oscillatory to net

flow (ψ).

This correlation has also been successfully

extrapolated and validated at 50 mm diameters.

Current work is focussed on

achieving scale-up through mass transfer (using

multi-orifice baffles) and heat transfer (using

regular orifice baffles), as these will have

implications on other types of process (e.g.

biological processes).

|