|

Reactive Extraction of

Biodiesel

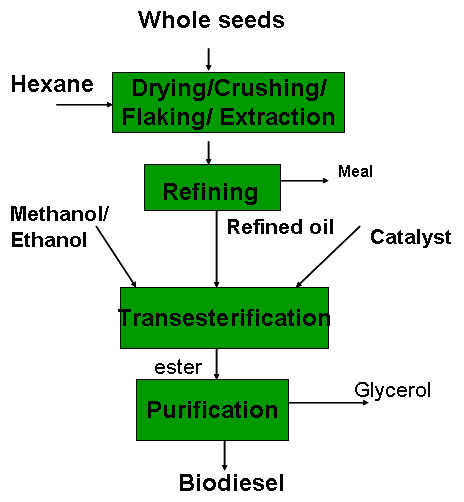

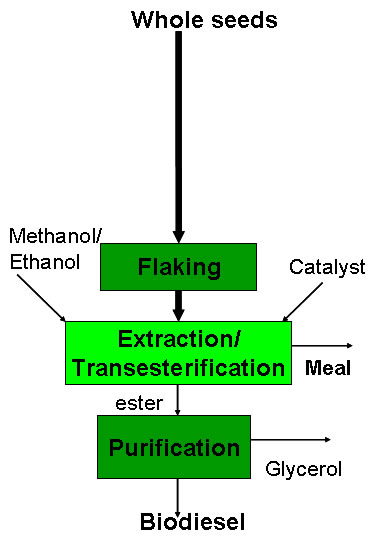

In the current processes for

biodiesel production, pre-extracted oil which is

usually degummed and refined is used as the

starting material. However, transesterification

of the oil can actually be carried out directly

from the plant seeds without prior extraction.

This route will simplify and improve the

efficiency of the methyl ester production

process as well as has the potential to reduce

production cost. Using this technique, the use

of hexane to extract the oil can be eliminated

as the extraction is being carried out by the

reactant itself.

Conventional

Transesterification |

Reactive

Extraction/In

Situ

Transesterification |

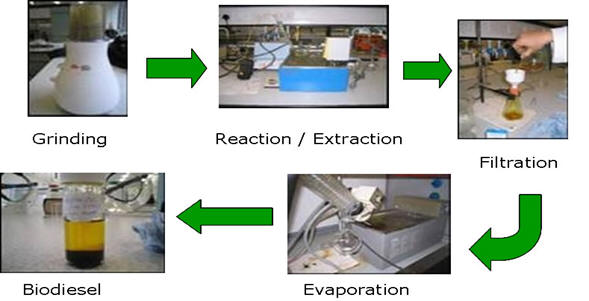

In the current study, the

steps and parameters involved in the integrated

extraction/reaction scheme will be investigated.

The optimum values for methanol/oil molar ratio,

catalyst concentration and temperature may

differ between conventional transesterification

and the combined reaction/extraction scheme.

Parameters that affect extraction such as seeds

pretreatment, particle size, moisture level, and

solvent amount will also be evaluated. A more

suitable catalyst may also need to be identified

since the common alkaline catalyst for

transesterification is adversely affected by

water, which is inevitably present in the seeds.

Reactive Extraction

Process Flow

For more information please

contact Prof Adam Harvey.

|