|

Catalytic conversion of

microalgae for biofuel production

Microalgae are aquatic

biomass that grows naturally in salt and fresh

water. Cultivation of microalgae has gained a

lot of attention due to its high growth yield,

cultivation in saline and fresh water and carbon

dioxide efficiency. These algal cultivation

properties make it one of the most sustainable

sources of biomass when compared to terrestrial

biomass such as forest biomass and cultivated

crops.

Biomass conversion processes

are classified into three major groups,

biochemical, thermo chemical and chemical

separation.

My research focuses on pyrolysis and

catalytic cracking of microalgae which has an

added advantage over other thermochemical

conversion processes, such as gasification,

direct combustion and liquefaction. Pyrolysis

and catalytic cracking has an established simple

process that occurs at relatively mild

conditions.

This research will

investigate the effect of temperature and

catalysts on the yield and physico-chemical

properties of the biofuel product (bio-oil,

biochar and biogas) on pyrolysis and catalytic

cracking of microalgae (Chlorella vulgaris and

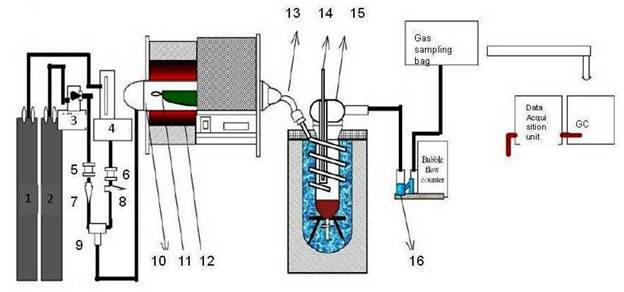

Nannochloropsis oculata). The experiment will be

carried out in a fixed bed reactor in a helium

flow with a rapid cooling of condensable

volatiles in a dewar flask containing dry ice as

shown in Figure 1.

Thermogravimetric studies of

samples used in pyrolysis and catalytic cracking

as well as the bio-oil products will be carried

out using a simultaneous thermogravimetric

analyser (TGA-DSC) to determine the pyrolytic

characteristic and thermogravimetric parameters.

Fig 1 - Schematic

diagram of experimental set-up

(1. Air bottle 2. Helium

Bottle 3. Flow meter 4. Rotameter 5 & 6.1/8

check valves 7 & 8. One way valves 9. 1/8 Union

tee10. Reactor 11. Sample boat 12. Furnace13.

Connection joint 14. Thermocouple 15. Coiled

condensing trap 16. De-ionized)

For

more details please contact

Prof. Adam Harvey

or

Dr Jonathan Lee.

|