|

Catalytic Plate Reactors

Supplying heat directly into

an endothermic reaction, rather than via

inter-stage heaters or by radiation to a packed

tube is a vital key to intensifying many

important chemical processes. The catalytic

plate reactor (CPR) offers an attractive route

for achieving this. In a CPR, metal plates

coated with a suitable catalyst are arranged in

such a manner that exothermic and endothermic

reactions take place in alternate channels (Fig.

1). These channels typically have a height of

order of millimetres and a catalyst thickness of

the order of microns.

Fig. 1 - A pair of adjacent channels in

the catalytic plate reactor

The research work at the

Process Intensification Group of Newcastle

University has focused on the development of a

detailed theoretical study on CPR's with the aim

of providing a base line for a general design

procedure. The advantages of CPR designs over

conventional reactors arise due to excellent

heat transfer characteristics and minimal

intra-catalyst diffusion resistance. The heat

transfer mechanism within a CPR is via

conduction through the plates separating

alternate process channels and as such is

largely independent of the process gas

superficial velocity. The catalyst layers within

a CPR are thin which results in minimal

diffusion limitations and thus high catalyst

utilisation. These advantages result in reactors

which are smaller, lighter and with a small

associated pressure drop than conventional

alternatives. The potential saving in reactor

volume can be seen in Table 1, below:

Table 1 - Size reduction through CPR

utilisation

|

|

Reaction |

Current

Technology |

Size

Reduction Factor |

|

|

|

Steam Reforming |

Packed Tubes in

Furnance |

>100 |

|

|

|

Fischer Tropsch

Synthesis |

Slurry Bed

Reactor |

4 |

|

Catalytic Steam Reformer

The feasibility of the concept

of coupled endo and exothermic reactions has

been demonstrated using steam reforming of

methane as the fast and highly endothermic

reaction with the energy being provided by the

catalytic oxidation of methane. Potential

exploitation of this system includes on-board

hydrogen production for fuel cell powered

vehicles, which are of particular interest due

to stringent legislation for the control of

automobile exhaust gases. This is possible due

to the significant size reduction (see Table

1). Another important application is the

production of syngas, which is the feed-stock

for many industrial processes. Methods for

preparing and coating the catalysts (based on

sol-gel technology) have been developed and the

necessary activity to achieve a targeted heat

flux of 10kW/m2 demonstrated.

The replacement of the

homogeneous combustion used in conventional

reactors by the catalytic one brings several

advantages. It proceeds at lower temperature

than conventional combustion, posing fewer

constraints for materials of construction and

producing virtually no NOx. Since it is a

flameless process, long radiation paths needed

in conventional fired furnaces are replaced by

channel dimensions of one or two mm, with an

obvious impact on reactor size.

Fig. 2 - Design of simple

CPR by using stacked diffusion bonded shims

(manufactured by Chart Exchangers)

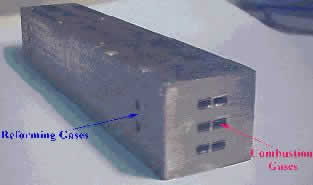

An example of the reactor

design where methane combustion and reforming

are integrated is shown in Fig. 2. The device

used in experimental work is shown in Fig. 3.

These devices are produced from patterned metal

shims which are stacked together and diffusion

bonded yielding a compact metal block.

Fig. 3 - Bench scale CPR

for methane steam reforming

An additional important

benefit of this concept is that the production

scaling can be handled through replication

rather than re-sizing. This leaves the reactor

performance effectively the same at all scales,

thus reducing the time requirement from

development to commercial production.

Methane Reforming in a

Catalytic Plate Reactors

The potential of the CPR for

dry or mixed reforming is currently being

investigated. In the process methane, steam and

carbon dioxide are simultaneously passed over a

nickel based catalyst. The technique has been

shown to strongly influence both the the CO:H2

ratio and rate of carbon laydown. A parametric

study is underway in an effort to minimise coke

deposition whilst producing a CO/H2 ratio which

is suitable as a feedstock for Methanol or

Fischer Tropsch processes.

Fischer-Tropsch synthesis in a

CPR

A second application of the

CPR is product enhancement for catalytic

reactions where the product spectrum is highly

dependant upon catalyst temperature. In such an

application alternate channels contain a boiling

heat transfer fluid to maintain an isothermal

catalyst temperature. To demonstrate the concept

the Fischer-Tropsch (FT) reaction has been

investigated.

The hydrocarbon product

spectrum produced by a FT catalyst is highly

dependant upon catalyst temperature and rate of

diffusion of reactants into the catalyst matrix.

The reaction is highly exothermic and if rates

of heat removal from the catalyst are not

sufficiently high "hot-spots" will form which

will result in degradation of the product

spectrum. Studies have revealed that thin

catalyst coats attached to heat transfer surface

areas within a CPR can greatly enhance the yield

of desirable products per unit volume as

compared to conventional fixed bed technology.

This volume saving coupled with an overall

lighter design, requiring less ancillary

equipment and with a low pressure drop make the

FT CPR a potential reactor for the recovery of

stranded gas reserves.

|