|

The production of polymer

nanocomposites using intensified modules

The advent of a new

generation of polymer nanocomposites in recent

years has resulted in the emergence of

substantially improved engineering and

structural materials with enhanced mechanical

properties. Such materials comprise a wide range

of conventional homopolymers and filler

materials such as treated clays, inorganic

particulates, carbon nanotubes and glass fibres.

To date, the focus of much of the literature has

been on the conception and testing of new

nanocomposites and their properties,

particularly clay-based systems, and to a lesser

extent particulates. However an efficient,

continuous method of generating such materials

has yet to be developed.

Process Intensification,

(PI), is a strategy which entails the reduction

of process volume without a decrease in product

throughput. Its aim is to enhance mixing and

improve mass and heat transfer rates and so

optimise the conditions for effective chemical

reactions. This should result in improved

conversion and product quality, as well as

reducing waste through improved selectivity.

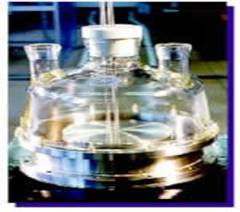

Fig. 1 -

Spinning Disc

Reactor |

Fig. 2 - Barium

Sulphate

Crystals (0.2 -

0.7 mm) |

PI offers the potential to

produce particulate-based nanocomposites in a

continuous mode which optimises the necessary

conditions for the three key processes of

polymerisation, nanoparticle production and the

effective mixing of the two composite elements

of particle and polymer.

The Spinning Disc Reactor,

SDR (Figure 1), has been employed for the

synthesis of poly(methyl-methacrylate) by means

of photo-initiation under ultra-violet light at

25°C. It can be operated as a one-pass reactor

or used to recycle a polymerising mixture until

the desired mass yield and molecular weight

properties have been achieved. The aqueous

production of particles to sizes of the order

0.1- 0.7 mm, (Figure 2), has also been indicated

on SDR and spinning cone devices suggesting the

possibility of an integrated reaction and mixing

process where polymer and particle can be

generated and inter-dispersed simultaneously.

The development of such a process is the primary

objective of this project.

The project has been in

progress since November 2002 and is due for

completion in February 2006. The principal

sponsors are Protensive Ltd. and the Engineering

Physical Sciences Research Council, (EPSRC).

Additional collaborators include Drs. K.V.K.

Boodhoo, (supervisor) and W.A. Dunk, (Protensive

Ltd., Newcastle).

For more information please

contact Dr Kamelia

Boodhoo.

|