|

Advanced Thermal Management

Techniques for High Power Electronic Devices

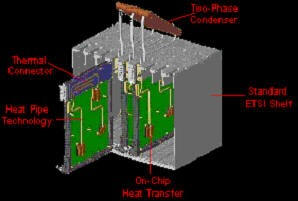

The introduction of more

densely populated electronic processing systems

utilising high power processing chips with

heat fluxes up to 250Wcm-2 has caused the limits

of conventional forced air convection cooling

techniques to move towards their thermal limits

and a requirement for advanced thermal

management systems to dissipate in excess of

20kW per server cabinet in 3G and 4G systems has

emerged.

In collaboration with

Industry (Thermacore

Europe) a project is being carried

out to develop passive cooling systems using

two-phase heat pipe technology to transport heat

to a remote location where it can be dissipated

more easily using liquid cooling or enhanced

forced air convection techniques (fig. 1).

Fig. 1 - Forced air convection therma

bus

Minichannel Liquid Cold

Plates

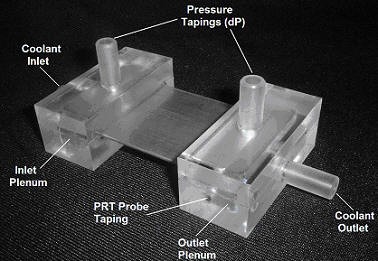

An on-chip

minichannel cold plate prototype (fig. 2)

manufactured from 1.5mm thick, 42mm wide

Aluminium extrusion with 35 x Ø750µm circular

microchannels running through its cross-section

doubles the heat transfer surface area available

for forced liquid convection when compared to

the surface area of the flat plate.

Laminar flow investigations of water through the

channels found that the temperature of a

simulated chip could be maintained below the

specified maximum temperature of 70°C whilst the

chip power was able to be increased from 120W to

320W.

Fig 2

- An on-chip minichannel cold plate prototype

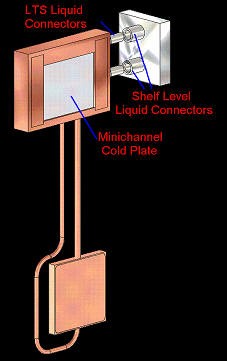

In heat pipes, the transport

of heat between the evaporator and condenser

sections is limited by opposing pressured of the

vapour and the returning condensed liquid.

Loop thermosyphons overcome this limitation by

having separate liquid and vapour lines to form

a loop. Flow of vapour and liquid

causes a circulation around the loop allowing

the fluids to to circulate in the same

direction, enhancing the performance of the

device. The industrial 'Therma BusTM'

project uses the LTS to transport heat from the

processing components to the rack level cooling

system. Figure 3 shows two LTS's

transferring heat from two processing chips to a

liquid cold plate at the top of the board.

The largest thermal resistances in this system

are across the thermal interface between the

chip and the LTS evaporator and from the LTS

condenser to the Liquid Cold Plate.

Loop Thermosyphon (LTS)

Fig. 3 - PCB with 2 x LTS and

Liquid Cold Plate

Combined Liquid Loop

Thermosyphon

By combining a minichannel

cold plate with an LTS to form a vapour to

liquid heat exchanger, a more compact system is

produced with a lower thermal resistance due to

the elimination of the thermal interface Layer

(fig. 4).

Fig. 4 -

Minichannel cooled LTS

For more information please

contact Dr Jon Lee

or Prof David Reay.

|