|

Microreactors

Improved methods of

manufacturing at the micro scale are opening up

new avenues for the development of compact

devices for functions ranging from reactions to

extraction and separation. Much of the initial

work in this field has concentrated on the

development of systems using single phase flow

with diffusive transfer between parallel

reacting fluid streams.

Work within our department has

however focused on the more complex system of

multiphase flow in narrow channels and in

particular immiscible liquid-liquid processes.

The main method adopted to perform multiphase

reactions is the use of slug flow to allow both

convective and diffusive processes to operate

within the reactor channel. An illustration of

the mechanisms involved is provided in the

diagram below.

Circulation

patterns within slug flow provide high mass

transfer performance between phases

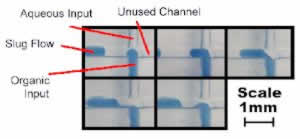

Generation of Slug Flow

Slug generation within glass

or polymer based on-chip style reactors is

generally achieved by the continuous pumping of

both phases into a “T” or “X” channel

configuration. The photograph below shows the

generation of slug flow for a two-phase

oil-water experiment being performed on a glass

chip with 0.38mm wide/deep channels.

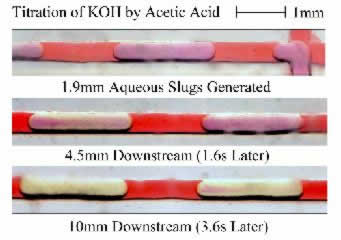

Reaction Visualisation

Flow visualisation of reaction

and mass transfer between slugs was performed as

part of the on-going modelling of slug flow.

A titration process involving

acetic acid transfer from kerosene into an

aqueous solution of NaOH and KOH was used to

visualise the mass transfer. This triggers a

colour change in a pH indicator as show in the

photograph below. In this example the aqueous

slug turns completely yellow after at least 50%

of the acetic acid has transferred, which in

this case occurred after 3.6s.

Use of Slug Flow for Chemical

Production

Experiments using slug flow

reactors were also performed for the

industrially relevant process of organic

nitration. A PTFE capillary tube reactor was

used with slug flow generated by use of a

modified tee as shown here.

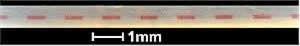

Images of slug flow generated

by this device using a dyed organic phase are

shown in the photograph below. In this system a

0.15mm internal diameter PTFE tube was used to

carry the slugs.

Results

from Benzene and Toluene nitration shown that

slug flow could be used to provide significant

conversion to nitrobenzene and nitrotoluene in

seconds using coiled PTFE reactors of 30cm to

180cm length and compared favourably with

industrial processes.

|