|

Polymer Film Compact Heat

Exchangers (PFCHEs)

The Process Intensification

Group at Newcastle University has developed a

novel concept of thin film polymer heat

exchangers that offer high thermal efficiency,

reduced fouling, significant reduction in weight

and cost, resistance to chemically aggressive

fluids and the ability to handle both liquids

and gases (single and two phase duties). This

provides PFCHEs, a competitive edge to their

metal counterparts.

The units are of compact

construction and can be of square or spiral

configuration. An important feature of the heat

exchangers that sets them apart from those on

the current market, is the use in some variants,

of a high temperature polymer, poly ether ether

ketone (PEEK). PEEK has a continuous use

temperature of up to 220°C. Although the thermal

conductivity of the polymer is not as high as

metals, the PFCHE made of 100 micron thick PEEK

films offers negligible thermal resistance when

the heat transfer coefficient is less than 4000

W/m2K.

|

|

|

|

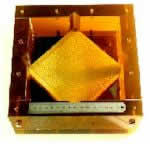

Corrugated

PEEK Sheets |

Square PFCHE |

Spiral PFCHE |

The potential market

opportunities are very wide ranging and include

applications in the chemicals and food and drink

industries, with possible applications in

generic equipment such as condensing boilers and

refrigeration plants. There are also

opportunities in the aviation, fuel cell and

automobile industries in the form of cabin air

coolers, filter coolers and radiators. Case

studies on the PFCHEs as a metal alternative in

the aviation and fuel cell industries have been

carried out using heat transfer and pressure

drop correlations developed from different fluid

systems. The fluid systems investigated are

air/air, water/water and glycerol water

mixtures/water for the square PFCHE whilst a

water/air system was studied for the spiral

PFCHE. The results are very positive as it

involves huge cost and energy savings.

Studies on the effects of the

corrugation angle and Prandtl number on the

performance of the PFCHEs are also underway.

Bonding issues have been addressed and among

methods suggested are laser welding,

co-extruding using different materials and using

epoxy fillers/ thin sheets with screen printing.

The issues of cheaper and more cost effective

means of handling the heat exchanger polymer

film are also being looked into.

With these benefits, it is

hoped that, at a later stage, useful heat

transfer and pressure drop correlations

developed for different fluid systems obtained

involving different PFCHE configurations over a

range of Reynolds numbers would enable

alternative compact industrial designs to be

realised.

Table 1 below, shows a

performance comparison of PFCHE with

conventional metal heat exchangers for an

air/air system using the heat transferred per

unit matrix volume. It clearly shows that the

PFCHE has a much higher heat transfer capacity

than conventional metal units and highlights the

advantage of the extreme compactness of the

PFCHE.

Table 1 - Heat Transfer

per Unit Matrix Volume (Air/Air)

|

|

Type |

Z (MW/m3) for ΔT

= 5°C |

|

|

|

Serrated Fin

(SF) |

0.60 |

|

|

|

Wavy-Fin (WF) |

0.27 |

|

|

|

Flat Tubes (FT) |

0.16 |

|

|

|

PFCHE |

1.09 |

|

|